crusher mill products crushers roller crusher

مجال التطبيق

خط إنتاج معالجة البوكسيت 200TPH في غينيا

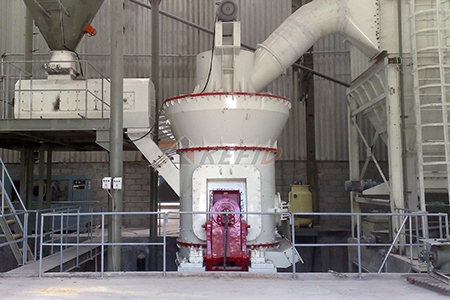

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

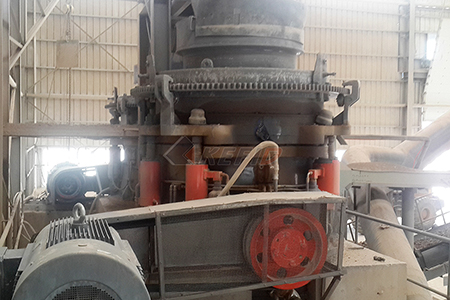

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

Roll crushers – ERC and double roll crusher – FLS

FLS Double Roll Crushers are capable of impressively high throughput rates – up to 14,000 tph

Roller Mills Roll Crushers CPM

Our roller mills are the choice for efficient barley malt crushing. Available in two-, four- and six

Crushers - BEUMER Group

Our product range includes impact, single, double and shear roller crushers as well as continuous roller and hammer crushers. FAM designed crushers are used for crushing minerals, raw materials and other bulk commodities.

Roller Mills Roll Crushers - CPM

Roskamp roller mills and roll crushers deliver a consistent, uniform grind for every application imaginable. Engineered to give you precise particle size control, Roskamp roller mills and crushers are built on a strong, solid foundation and

Roll Crusher HRC - HAZEMAG

HAZEMAG Roll Crushers offer significant features and benefits: Low specific power

Roller Mills - Roll Crushers - Flakers - Bauermeister

Bauermeister’s Roller Mills/Roll Crushers are used for crushing a variety of soft to medium-hard products providing high throughput with narrow particle size distribution. The creation of undesirable fine particles is reduced by subjecting

Roller Mills by SIEBTECHNIK TEMA. Crushing milling

Our laboratory roller mills have an innovative app control, a continously adjustable roller gap, reversible overload protection, high fore transmission to the moving grinding roller and a dust extractor connection. Via the flap-open upper

Roller Mills Roll Crushers 1600 Series CPM

Roskamp Roll Crushers are designed for the most demanding crushing applications, with roll corrugations and roll speed differential ratios available to match any operating conditions. Available in two-, four- and six-roll designs,

rock crusher,stone crusher,double roll crusher,roller

Huashengming Heavy Machinery Factory - Crusher, Stone Crushing Equipment, aggregate processing equipment, Roll Crusher Sieving Equipment for sand, quarry, mining and construction. Manufacturer from Gongyi City, Henan

Joyal-Stone Crushers,Grinding Mills,Jaw Crusher,Impact Crusher

Joyal-Stone Crushers,Grinding Mills,Jaw Crusher,Impact Crusher,Cone Crusher,Roller Crusher,High Pressure Mill,Three-ring Micro Mill.Joyal is a professional manufacturer of Jaw Crusher, Impact Crusher, Cone Crusher, ZYS Cone Crusher,aggregate crusher machine,Raymond mill, Grinding Mill,if you want to know more information,you can contact us!

Roll Crushers - HAZEMAG

Roll crushers with smooth rolls are used for pulverization to generate a product granulometry of ≤ mm. To provide optimum protection for the roll crusher, a hydraulic floating roll retraction system has been developed based on the successful system used in HAZEMAG impact crushers.

Roller Crusher - Shalimar Engineering

World’s Largest Manufacturer and Supplier of Roller Crusher Machine Manufacturer. A roll crusher crushes using compression, with two rolls rotating about a shaft, toward the gap between the rolls.The gap between the rolls is set to the size of the product desired, with the realization that the largest feed particle can only be 4 times the gap dimension.

What Are the Differences Between The 7 Types of Crushers?

2024年7月15日 Manufactured sand made by roll crusher in Indonesia. The video shows the double roller crusher is turning small-sized stones into manufactured sand. There is a certain gap between the two counter-rotating rollers. Changing the gap can control the product size, shapes, and fineness modulus.

Slugger Crusher Hammer Mill Learn More at Williams Crusher

With over 500 patents and 150 years of business in its name, Williams Patent Crusher has solidified its place at the forefront of particle size reduction technology. Features of the Williams Slugger Crushers. Williams Slugger Hammer Mill Crushers are an ideal choice for applications requiring a large feed opening.

2PG Roller Crusher > Crushing Equipment > Products > DSMAC

2PG Roller Crusher is ideal for 1.Double roll crushers are used for both, primary and secondary crushing. They guarantee a strictly defined final grain size with a minimum of fine grains; 2. Raw materials, secondary materials and by-products such as coke, sinter, coal, soft to medium-hard rock, ore, chalk, broken glass and similar products.

Smooth Roller Crusher - huashengming

Smooth Roller Crusher is also called double-roller crusher and double roller sand making machine. It uses two motors to drive two pairs of rollers to squeeze and grind materials. Fine crushing operations where the roller crushing degree is less than 80mm and the finished product particle size is required to be 50 mesh-20mm. Why choose ...

Roller Mills Roll Crushers - CPM

ROSKAMP ROLLER MILLS ROLL CRUSHERS—MASTERS OF THE DAILY GRIND. ... solid foundation and equipped with solid rolls for long life and reliability. With CPM as your roller mill and roll crusher supplier, you'll get great ... Interactive Model. 650 Series. 900/999 Series. 1200 Series. 1600 Series?> × CPM Roller Mill Interactive Model. 1 . 2 ...

What’s a Double-Roller Crusher? - Eastman Rock Crusher

2022年2月10日 The double-roller crusher should strengthen the iron removal work of feeding ore. Non-crushing objects (bits, etc.) falling into the pair of rollers will damage the crusher, resulting in a parking accident. Therefore, an iron removal device should be installed before the crusher. The viscous material is easy to block the crushing space.

Roller Crusher – Nesans Mining and Automation

Nesans CI Series Double Roller Crushers are unique Quaternary stage crushers designed for ultra-fine reduction required for plastering purpose manufactured sand. Furthermore, Efficient torque sharing between the rolls and frequency

Crushing Technologies - thyssenkrupp Polysius

Travel distances and the number of trucks can thus be optimized to the greatest possible extent, thus also reducing CO2 emissions. At the new Yamama Cement Co. site, not only two of our mobile crushers are used, but also three

Hammer Crushers - HAZEMAG

Double rotor Hammer Crushers are able to process materials with a moisture content of 10 – 15 % without requirement for additional heating. In case of feed two different materials at the same time (e. g. limestone and clay), they are very well mixed in the crushing process.

Roller Mills - SIEBTECHNIK TEMA

Single-roller mill. With the single-roller mills, brittle, soft to medium-hard materials can be reduced in size with a reduction ratio of approx. 1:5 to 1:5. The stepped arrangement of the crushing jaws on the crushing wall enables any material rolling off being minimised, so that, compared to the double-roller mill, coarser material can be ...

Roller Crusher

Roller Crushers are the product of over a century of experience. Each is designed to the highest engineering and construction materials standards. This assures you the ultimate in trouble-free operating efficiency, minimum and simplified maintenance and long service life.

Jaw Crusher VS Roller Crusher - Baichy

2023年6月29日 Jaw crushers are mainly used for coarse crushing and medium crushing processes, and roller crushers are fine crushing machines. What is the difference between jaw crusher and double roller crusher? Let's move on to the following items to know about difference. 1. Applicable material

Roller Pulverizer For Ferro Alloys Grinding - Crusher Mills

Grinding Mill; Vertical roller mill ; Raymond mill ; Ball mill; MTM series grinding mill ; 29/04/11 The Pakistan market for manganese ferro-alloys is slow at the Coke Crusher Machine in Malaysia,Coke Crusher Machine

Roller Crusher Design Crusher Mills, Cone Crusher, Jaw Crushers

Roller Crusher (PG)-Roller Crusher (PG) specifications,price 3) Compact design; 4) Environment Protection; 5) Long life. Application of Roll Crusher Roll crusher can be applied in industrial sectors such as ore dressing

Roll Crusher -Ore Crusher - Forui Mining Machinery

The roller crusher is designed to handle the secondary and tertiary stage crushing of friable materials such as coal, salt, bauxite, limestone, barite and other minerals withstand crushing strength ≤160 MPa in the mining, power generation, recycling and other industries. Forui roller crusher uses two rotating rollers to crush the material.

Roller Crusher

The Double Roller Crusher, also known as roll crusher, toothed roll crusher, is suitable for fine crushing the medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, clinker, ceramic raw materials, slag, refractory materials, and chemical materials.

سابق: مصنع الخرسانة الخلوية

التالي: مطحنة كيف يعمل

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت